Click here -> to go to the Table

of Contents

Printer Setups

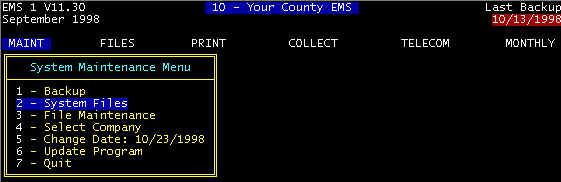

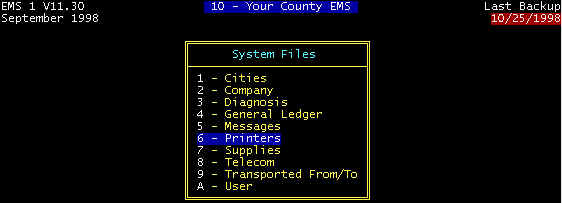

Menu Path: MAINT/System Files/Printers

The PRINTER file allows

multiple printers to be attached to a single computer or workstation, either directly or

indirectly via a network. Also, as multiple configurations of a single printer

dependent upon the form and/or report being printed. Additionally, the physical

characteristics for the printer can be matched to the forms/reports being printed--for

example, the paper-load position, margins, etc. can be matched to the printout such that

manual adjustment is not required.

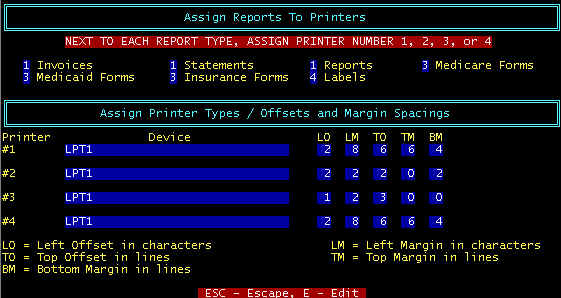

As shown, three logical printers and a label printer can be assigned to

the printed reports.

Printers are assigned an output

port such as LPT1, LPT2, etc., and this is due to the the of interface board inside the

computer to which the external printer is connected, plus some other software

configuration program is set, and this is standard procedure for all type computer

programs.

Printer assignments via the printer screen serves several

purposes:

tto set

margins and offsets in order to position the printed data to compensate for both the

automatic load position and feeding mechanisms of specific printers, as well as the

different positioning required for the different forms and paper used, without the need

for manual adjustment of paper position after the auto paper-load ; tto route certain printed reports

to one printer, certain reports to the second printer, and certain reports to the third

printer. If more that one printer is used, this allows different types of forms, paper,

etc. to be in place without having to change paper each time a different paper/form is

printed; tbut most

often, to allow different print positions for data using the same printer - the example

above uses a single printer (LPT1), but different print positions for forms as for

reports.

In the printer screen above, printer #1 is assigned to the following

reports: Invoices, statements, and reports. Printer #2 is assigned to Medicare 1491,

Medicare 1500, and Medicaid.

Printer device listed on the screen as Device, usually refers to

the computer device (or disk file - see below) to which the program routes the data to be

printed.

Redirecting the printed output through the network to a printed

connected to another computer on the network is done by assigning this output to device

LPT3. Assigning and using shared network printers should be done reservedly, with problem

areas described later. Printer device assignment is done in two places:

Œ

The network printer setup software may be difficult and

complicated to access, and this is typically done by the system installer. For example,

the network printer may be defined as LPT3. Thus if a work station assigned a printer (via

the printer screen shown above) to LPT3, then reports assigned to this printer (physically

located remotely from the workstation) would be routed (spooled) to the network printer

via the network software.

Printer device assignment must also be done at each workstation

via each printer screen, but using the same device (LPT3 for example) as the network

software as described immediately above.

There are both advantages and disadvantages of sharing printers via the

network, and the disadvantages usually outweigh the advantages. First the advantages.

Obviously fewer printers are required. Additionally, a very high speed (more expensive)

printer can be used for possibly faster operation.

Now the disadvantages:

t

the person selecting the printed output is not located at the printer to observe

printer jams, out of paper, etc.

t

printing

does not commence until the file has completed transmission via the network to the network

computer to which the network printer is connected.

t

in

case of printer "busy" conflicts, the requested printed outputs are put in a

network printer "queue", and printed when the printer finishes reports in the

order of this "queue". In case of a printer paper jam, forcing the printer to go

busy, as well as requiring that the report be re-printed, a network application program

must be run to free the condition.

If a file name (only) is specified

under the device heading for printer #3, for example file name TEST.PRN, the data intended

for printing on printer #3 will be stored on the current disk drive, and in the current

directory/subdirectory as TEST.PRN (in most cases C:\EMS\TEST.PRN). If a drive, path, and

file name (C;\TEST\TEST.PRN, for example) are entered under the device heading for printer

#3, reports directed to printer # 3 will be written to the specified drive and directory

as file TEST.PRN , and in this example located on the C: hard drive, subdirectory TEST

(note that the system must have a C-Drive, as well as a TEST subdirectory). The file that

is stored with file name TEST.PRN is in a "text" format that can be read into

most word processing and data base programs for whatever reason. Once read by the word

processor, editing, formatting, etc. can be done for whatever reason.

Note that TEST.PRN is overwritten every time a printout is directed to

printer #3, and thus, immediately after recording a printout as TEST.PRN, go into the

subdirectory and rename TEST.PRN to TEST2.PRN (for example), otherwise the file will be

overwritten, the next time a printed output is directed to printer #3.

Most modern printers have an automatic

paper-load feature, but different manufacturer's printers may end up with the paper in

different positions; this can even vary side-to-side for identical printers, depending

upon the tractor pin-wheel lock-down positions. It is desirable to automatically load

printer paper and leave in the auto-load position without the need for further manual

adjustment. Adjusting the print position to compensate for auto-load paper positions is

accomplished via "Offset and Margin Spacings" parameters as described

below. Note that the effect of these print positioning parameters is difficult to describe

and understand, thus an overview of horizontal (across the width) positioning and vertical

(up and down) positioning is presented before parameter details are described. For the

discussions below, note that there are 80 print positions for each line, and a maximum of

66 lines per page.

There are certain parameters

that are used to position the printed information on the statements, invoices, reports,

and forms, as defined below; positioning of printed information on forms is most critical.

There are two parameters that

determine the physical limitations of the printer, and these are the offsets. For example,

a particular printer may not be physically able to print any nearer the left edge of the

paper than a blank space or 2 characters, and thus LO=2 for this printer. Similarly, this

printer may not physically be able to print any nearer to the top edge of the paper than

three blank lines, and thus TO=3. Note that laser printers can printer nearer the edges in

GRAPHICS MODE, but we are not interested in graphics mode. The way to

determine TO and LO is to get to the root directory of your hard drive and from your

keyboard, type:

COPY<space>

AUTOEXEC.BAT<space>LPT1<enter>

This will transfer a file to

the printer in non-graphics mode. Measure the number of blank character spaces between the

first character printed to the left edge of the paper and this number is the left offset

– LO. Similarly, measure the number of blank lines between the first printed line and

the top edge of the paper, and this number is the top offset – TO. You have measured

the physical margin limitations of your particular printer. After entering these offsets,

zero-in with the positioning with the top and left margins TM and LM, except for forms,

and these two settings are always 0 (zero) for forms, but for other reports cannot be less

than the offsets, as described below.

LM - this is the desired

left margin. Increasing by one moves the printed area to the RIGHT one character

position. Zero for forms, for reports, minimum value of the LO value

LO -- this is the computed left offset . Increasing by one

moves the printed area to the LEFT one character position.

TM -- this is the desired top margin. Increasing by one

moves the printed area DOWN one line, thus having the effect of REDUCING the

number of printed lines on a page by one, and at the same time moving the line that was

previously at the bottom of page one to the top of page two. TM=0 for forms, minimum value

of TO for all reports

TO

-- this is

the computed top offset. Increasing by one moves the printed area UP one

line, thus having the effect of INCREASING the number of printed lines on a page by

one, and at the same time moving the line that was previously at the top of page two to

the bottom of page one.

BM -- this is the desired bottom margin. Increasing by one

increases the blank area at the bottom of the page by one line, thus having the effect of REDUCING

the number of printed lines on a page by one, and at the same time moving the line that

was previously at the bottom of page one to the top of page two. The minimum value is the

number of blank lines that the printer cannot physically print.

Forms especially require printing in exact locations,

and settings for certain printers are shown below – note that for forms, the top and

bottom margins (TM and BM) are always set to 0. Position the printout by changing the

other parameters: offsets LO and TO, and LM. The offsets are the physical limitations of

the printers. Some printers can print on a larger area of the printable space. For

example, some printers are capable of printing three lines down from the top edge of the

paper, whereas other printers can print only as high as five lines down from the top edge.

Similarly with the Left margin. Thus these offsets are used to adjust the print to your

specific printer. To test the effects of changing TO and LO, go to print forms, print test

pattern. Adjust TO and LO for the best fit of the printed test pattern to the form.

Parameters for several popular printers is tabulated in figure 1.