|

|

|

|

|

|

|

|

|

|

|

Model 7 Brochure

Pattern Design

Screen Shots

|

|

| TC3000

- Model 7 |

|

Here Bill Otto is shown with the portable keyboard/display terminal

that has been used in all 200 previous control systems installed

over the past 12 years. All new systems are downward compatible

both from use and functionality of this terminal. The terminal is

connected to the computer via a long cable such that its position

can be in close proximity of a fixer (running diagnostic programs),

as well as the operator at the machine.

These same functions and displays are operational

via the computer keyboard and color monitor, with obvious additional

features available with the color monitor, displaying additional

information, patterns, for example.

As mentioned, the portable keyboard/display functions

are the same as older models, but also old pattern (diskette) files;

older patterns will run on the newer control systems. The portable

terminal functions are also operational via the computer keyboard

/ monitor.

|

|

|

|

| |

|

|

|

From the rear of the cabinet, the back of the monitor

is shown in the top, then the computer, then the interface card

rack – cables can be seen at the top of the cabinet. These

connect the circuits in the interface card rack to the solenoids

on the machine.

Some systems have a servo system under the interface

card rack (not shown here) that controls a servo motor on the machine.

The servo system operates in sync with the rug pattern such that

the backing is advanced in fixed steps. The backing motion begins

on the needle upstroke when the needles clear the backing, with

motion completion before the needles reenter the backing on the

downstroke. The step distance is part of the pattern, and determines

the stitch count, as well as eliminating backing motion when the

needles are in the fabric.

In the bottom are power filtering, isolation and

regulating components. The coil of cables at the bottom connect

to position sensors on the machine.

An air system can be seen on the rear door.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

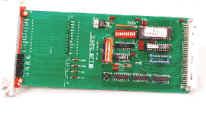

Industry standard Euro Cards

and racks are used. Each rack holds up to 20 solenoid interface pc

boards, with 64 output circuits per board, resulting in control capability

of 1,280 output signals per rack. The cabinet can hold 4 racks (extensions

can be added) for a total per cabinet of 5,120 control outputs. We

currently have a system quoted with over 14,000 outputs.

The (coiled) ribbon cable shown is connected to the back of the

card rack and has a machine wiring interface at the other end, depending

upon the application. In this case, there is a solenoid interface

pc board with a terminal strip to which machine solenoid wires are

terminated.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The solenoid interface pc board

connector pins come through the card rack backplane and the ribbon

cable connects directly to the solenoid interface pc board connector,

thus reducing the number of connections and in turn enhancing connection

reliability. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The front of the

solenoid interface pc board has 64 red LEDs in series with 64 corresponding

solenoids, and only illuminate when each corresponding solenoid is

drawing current. Hence, the LED is a true indication of computer,

circuit, and machine wiring integrity. The solenoid output circuits

are fused on the pc board so as to protect against both solenoid and

machine wiring faults; fuses plug into pin sockets for easy replacement.

Fusing other than on the pc board may not give complete protection.

On the pc board end plate is a number next to each LED for identification.

The illumination pattern of all pc boards is seen through a smoked

glass front panel.

Any pc board plugs into any slot in the rack. Each pc board has

an on-board power supply (regulator/rectifier) for both the pc board

power and solenoid power, so as to eliminate the need for two large

power supplies that could take out the entire system.

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A (programmable)

control pc board in each card rack allows configuration of the rack

to the specific machine. Some machines have multiple controls per

yarn end, such as high/low plus cut/uncut. Two control outputs are

needed per yarn end, and these outputs can be mapped on this board. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

This picture shows floor mats

coming off a production Colortec machine controlled by a model 7 CES

controller. |

|

|

|

|

Home | Products | News |

Downloads | Info |

|

|

|

|

|

|

|

|

|

|

|

|